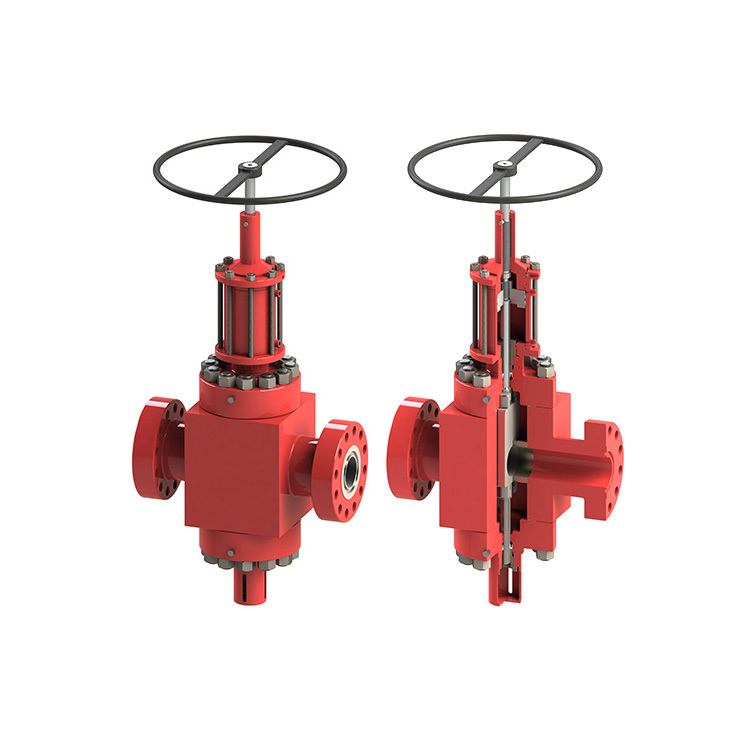

Manual Hydraulic Plate Gate Valve

• Full bore design effectively eliminates pressure drop and eddy currents, reducing erosion of the valve by solid particles in the fluid.

• Metal seals are used between the valve bonnet and body, between the valve disc and seat, and between the seat and body.

• The valve disc and seat surfaces are sprayed (welded) with hard alloy, providing excellent wear and corrosion resistance.

• Equipped with a balanced tail rod to balance the valve stem load, reduce the load on the valve stem threads and bearings, and lower operating torque.

• The valve bonnet and stem are designed with a back-seal structure, facilitating the replacement of the valve stem seal ring under pressure.

• A grease injection valve is designed on one side of the valve bonnet.

• Rising stem structure allows indication of valve open/close status.

• Various specifications of pneumatic (hydraulic) actuators can be equipped according to user requirements.

• Working pressure: 2000PSI~20000PSI

• Nominal diameter: 1.13/16"~9" (46mm~230mm)

• Working medium: petroleum, natural gas, mud, gases containing H2S and CO2

• Working temperature: -46℃~121℃ (LU grade)

• Material grades: AA, BB, CC, DD, EE, FF, HH

• Specification levels: PSL1~4

• Performance levels: PR1~2

Keywords:

Slab Gate Valve

Category:

• Full bore design effectively eliminates pressure drop and eddy currents, reducing erosion of the valve by solid particles in the fluid.

• Metal seals are used between the valve bonnet and body, between the valve disc and seat, and between the seat and body.

• The valve disc and seat surfaces are sprayed (welded) with hard alloy, providing excellent wear and corrosion resistance.

• Equipped with a balanced tail rod to balance the valve stem load, reduce the load on the valve stem threads and bearings, and lower operating torque.

• The valve bonnet and stem are designed with a back-seal structure, facilitating the replacement of the valve stem seal ring under pressure.

• A grease injection valve is designed on one side of the valve bonnet.

• Rising stem structure allows indication of valve open/close status.

• Various specifications of pneumatic (hydraulic) actuators can be equipped according to user requirements.

• Working pressure: 2000PSI~20000PSI

• Nominal diameter: 1.13/16"~9" (46mm~230mm)

• Working medium: petroleum, natural gas, mud, gases containing H2S and CO2

• Working temperature: -46℃~121℃ (LU grade)

• Material grades: AA, BB, CC, DD, EE, FF, HH

• Specification levels: PSL1~4

• Performance levels: PR1~2

Keywords:

Slab Gate Valve

Previous: Ball Screw Flat Gate Valve

Next: WKM Expanding Gate Valve

Product Inquiry Message

Related Product Recommendations